- Pressure and Safety Relief Valves

- Anderson Greenwood Crosby Whessoe Direct Spring Operated Pressure Relief Valves Series 60/80

- Anderson Greenwood Crosby Whessoe Liquid Storage Internal Tank Valves

- Anderson Greenwood Crosby Whessoe Marvac Model 910 Pilot Operated Pressure Relief piped vent

- Anderson Greenwood Crosby Whessoe Marvac Model 920 Pilot Operated Pressure and Vacuum Relief piped vent

- Anderson Greenwood Crosby Whessoe Marvac Series 500 Pressure and Vacuum Relief Valves

- Anderson Greenwood Crosby Whessoe Models Y1/BV1/RA Blanketing Regulator

- Anderson Greenwood Crosby Whessoe Reserve Capacity Relief Valve

- Anderson Greenwood Crosby Whessoe Safety Selector Valve

- Anderson Greenwood Crosby Whessoe Series 121 Pressure and Vacuum Relief Valves

- Anderson Greenwood Crosby Whessoe Series 121F Pressure and Vacuum Relief Valves

- Anderson Greenwood Crosby Whessoe Series 121V Vaccuum Relief Valves

- Anderson Greenwood Crosby Whessoe Series 200/400/500/700/800 Pilot Operated Relief Valves

- Anderson Greenwood Crosby Whessoe Series 5200 Pilot Operated Pressure Relief Valves

- Anderson Greenwood Crosby Whessoe Series 90/9000 Pilot Operated Pressure Relief Valves

- Emergency Relief Vents

- Flame Arresters

- Anderson Greenwood Crosby Whessoe 5910C

- Anderson Greenwood Crosby Whessoe Amal ERQ Endofline deflagration flame arrester

- Anderson Greenwood Crosby Whessoe Amal ERQB Flame Arrester

- Anderson Greenwood Crosby Whessoe Amal IRQ/IRQE Inline Deflagration Flame Arrester

- Anderson Greenwood Crosby Whessoe Amal LER/LERC/LEF/LEFC Endofline Deflagration Flame Arrester

- Anderson Greenwood Crosby Whessoe Amal LIR/LIRE Inline Deflagration Flame Arrester

- Anderson Greenwood Crosby Whessoe Amal LIRD/LIRDE Inline Detonation Flame Arrester

- Anderson Greenwood Crosby Whessoe Amal LSFE Liquid Seal Flame Arrester

- Anderson Greenwood Crosby Whessoe Amal NP/NPC Flame Arrestors

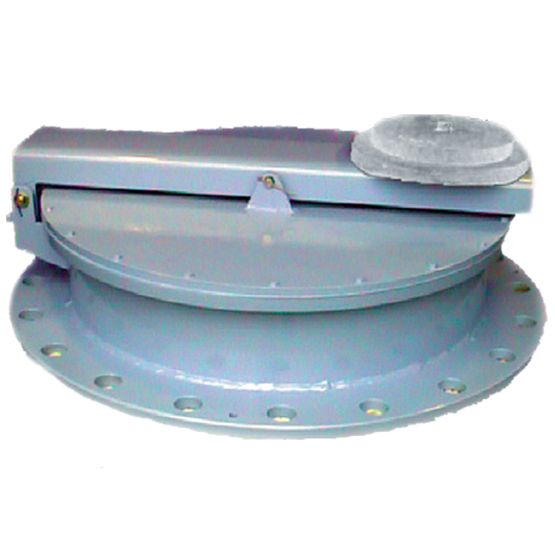

Anderson Greenwood Series 4210A Emergency Pressure Vent and Manway Cover

Provides access and emergency protection against costly ruptures.

- Hinged cover provides a fixed pivot point, ensures proper reseating and added safety.

- Cover cannot separate from the base.

- Easily lifted open to provide a large, unobstructed passage for easy tank access.

- ‘Tite seal’ diaphragm design ensures minimum vapor leakage losses to 1 CFH at 90% of setting.

- Durable PTFE seal backed by a non-asbestos cushion disc for added resiliency and reduced leakage.

- PTFE diaphragm protects the cushion disc from direct contact with tank vapors in chemical and low temperature applications.

- Carbon steel units have steel bases with a welded and machined stainless steel tip on the nozzle perimeter to ensure a corrosion resistant seating surface.

- Optional stainless steel bases for chemical and low temperature applications.

- Flange mounting dimensions conform to either API 650 or ANSI 150#.

Optional vacuum valve available in cover.